PRODUCTS

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details

Roller chain coupling AUTOCAD renderings (GB6069-2002 instead of GB6069-86) Features: The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. Chain couplings of different structural types The main difference is the use of different chains, such as double-row roller chain couplings, single-row roller chain couplings, toothed chain couplings, nylon chain couplings, etc.The performance of double-row roller chain couplings is better than other structural types of couplings, and is widely used at home and abroad, and our country has also formulated it as a national standard.

Details

Roller chain coupling AUTOCAD renderings (GB6069-2002 instead of GB6069-86) Features: The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. Chain couplings of different structural types The main difference is the use of different chains, such as double-row roller chain couplings, single-row roller chain couplings, toothed chain couplings, nylon chain couplings, etc.The performance of double-row roller chain couplings is better than other structural types of couplings, and is widely used at home and abroad, and our country has also formulated it as a national standard.

Details

Roller chain coupling AUTOCAD renderings (GB6069-2002 instead of GB6069-86) Features: The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. Chain couplings of different structural types The main difference is the use of different chains, such as double-row roller chain couplings, single-row roller chain couplings, toothed chain couplings, nylon chain couplings, etc.The performance of double-row roller chain couplings is better than that of other structural types of couplings, and is widely used at home and abroad. my country has also formulated it as a national standard

Details

Roller chain coupling AUTOCAD renderings (GB6069-2002 instead of GB6069-86) Features: The chain coupling uses a common chain and meshes with two parallel sprockets with the same number of teeth at the same time. Chain couplings of different structural types The main difference is the use of different chains, such as double-row roller chain couplings, single-row roller chain couplings, toothed chain couplings, nylon chain couplings, etc.The performance of double-row roller chain couplings is better than other structural types of couplings, and is widely used at home and abroad, and our country has also formulated it as a national standard.

Details

UL tire couplings are made into non-standard couplings according to special needs. When overloaded, the clamping flaps of the half couplings will work, and no malignant accidents will occur. Its structure is marked as M, standard half couplings The structure of the device is K-type, and it can no longer be marked in the display.

Details

Most of the flexible couplings are made of aluminum alloy, and some manufacturers also provide flexible couplings made of stainless steel.In addition to corrosion resistance, the stainless steel elastic coupling also increases the torque capacity and rigidity, and can even be twice as high as that of similar products made of aluminum alloy.However, this increased torque and rigidity will be offset to a certain extent by the increased mass and inertia.Sometimes the negative impact will outweigh its advantages, so users have to look for other forms of couplings

Details

Most of the flexible couplings are made of aluminum alloy, and some manufacturers also provide flexible couplings made of stainless steel.In addition to corrosion resistance, the stainless steel elastic coupling also increases the torque capacity and rigidity, and can even be twice as high as that of similar products made of aluminum alloy.However, this increased torque and rigidity will be offset to a certain extent by the increased mass and inertia.Sometimes the negative impact will outweigh its advantages, so users have to look for other forms of couplings

Details

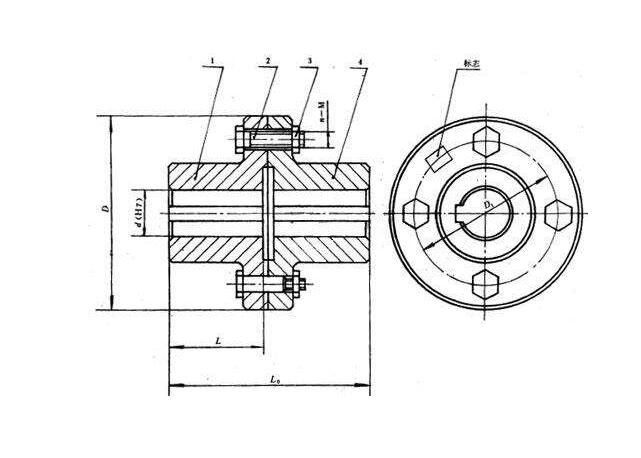

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, when the speed is low, there is no impact, and the rigidity of the shaft is large.

Details

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, when the speed is low, there is no impact, and the rigidity of the shaft is large.

Details

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, when the speed is low, there is no impact, and the rigidity of the shaft is large.

Details

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, when the speed is low, there is no impact, and the rigidity of the shaft is large.

Details