PRODUCTS

The material of the flange coupling can be gray cast iron or carbon steel, and cast steel or forged steel should be used under heavy load or when the peripheral speed is greater than 30 m/s.Flange couplings have high requirements for the neutrality of the two shafts. When the two shafts have relative displacement, they will cause additional loads in the machine parts and worsen the working conditions. This is its main disadvantage.However, due to the simple structure, low cost, and large torque transmission, when the speed is low, there is no impact, and the rigidity of the shaft is large.

Details

MAL type friction safety coupling is also called limited torque coupling...

Details

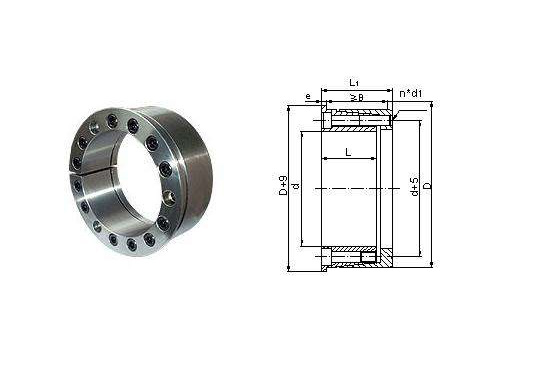

Z18型胀紧联接套(简称胀套)是当今国际上广泛用于重型载荷下机械联接的一种先进基础部件,在轮和轴的联接中,它是靠拧紧高强席螺栓使包容面间产生的压力和摩擦力实现负载传送的一种无键联接装置。另本公司还生产JB/T7934—1999标准的Z10、Z11、Z12A、Z12B、Z12C 、Z13、Z14及德国标准的KTR200、KTR201、KTR202、KTR203、KTR204、KTR205、KTR206、KTR208、KTR225、KTR400和美国标准的胀套

Details

The rated load of the Z13 expansion coupling sleeve when several expansion sleeves are used for one connection. When the rated load of the Z13 expansion coupling sleeve is less than the load to be transmitted, two or more expansion sleeves can be used in series. The total rated load is: Mtn=m.Mt where: Mtn--- total rated load of n expansion sleeves; m---load factor

Details

The Z19B expansion coupling sleeve can bear multiple loads, and its structure can be made into a variety of styles. According to the size of the installation load, multiple expansion sleeves can also be used in series. The technical points are: there is internal and external pressure between the outer ring and the inner ring The outer wall of the ring, inner and outer pressure ring is sloped, the bottom of the second ring is opposite, the inner wall of the outer ring, the outer wall of the inner ring are convex, and the concave shape of the outer wall of the pressure ring is mutually compensated, and there are gaps on the inner and outer rings. When the bolts are tightened, the inner and outer pressures move relative to each other. Under the action of the inclined plane, the inner ring begins to shrink, and the outer ring begins to expand outward to achieve the purpose of connecting the shaft and the hub. It has the characteristics of dispersing stress concentration, anti-fatigue strength, and avoiding the shaft Advantages such as disconnection. It is suitable for use when connecting shafts and hubs.

Details

When the expansion sleeve is clamped, each mating surface has a high pressure and is completely sealed, which avoids the corrosion of the mating surface.When disassembling, loosen the bolts, the mating surface is automatically loosened, and the shaft sleeve and cone ring automatically return to the original size. This device is easy to disassemble and assemble, suitable for medium and low speed torque transmission.

Details

The inner and outer cone rings of the Z15 type expansion sleeve are tightened with hexagon socket bolts. The joint surface is longer and the centering is good. It is suitable for occasions that require high rotation accuracy and transmit large loads.

Details

Z11 type expansion coupling sleeve characteristics: Z11 type expansion coupling sleeve is composed of a split double cone inner ring with different tapers, a split double cone outer ring and two double cone compression rings, which are locked with hexagon socket bolts.Compared with the Z2 type, the joint surface is long and the centering accuracy is high. It is used in the occasions that require high rotation accuracy and transfer large loads. Z11 type expansion sleeve has high positioning accuracy, simple hub hole and wide application.

Details

The elastic element of the coupling diaphragm is composed of a thin stainless steel diaphragm laminated into a diaphragm assembly. The diaphragm usually has a waist shape, a polygonal ring shape, etc., and the precision bolts on the same distribution circle are respectively the driving and driven flanges. Join.The diaphragm assembly bears the misalignment of the driving and driven flanges in the form of three-dimensional deformation.Our factory provides various diaphragm couplings. The material used for the diaphragm is imported stainless steel. After our patented technology-vacuum heat treatment and cryogenic treatment, it not only guarantees the strength of the material but also the toughness of the material.Welcome to map and customize.

Details

Several groups of diaphragms (stainless steel thin plates) are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and different shape of the whole piece type.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with strong metal components. It does not require lubrication, and has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance and corrosion resistance, suitable for high temperature, high speed, and corrosive medium operating conditions.

Details

Several groups of diaphragms (stainless steel thin plates) are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and different shape of the whole piece type.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with strong metal components. It does not require lubrication, and has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance and corrosion resistance, suitable for high temperature, high speed, and corrosive medium operating conditions.

Details

Several groups of diaphragms (stainless steel thin plates) are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and different shape of the whole piece type.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with strong metal components. It does not require lubrication, and has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance and corrosion resistance, suitable for high temperature, high speed, and corrosive medium operating conditions.

Details

Several groups of diaphragms (stainless steel thin plates) are alternately connected with the two halves of the coupling with bolts. Each group of diaphragms is composed of several stacked ones. The diaphragms are divided into connecting rod type and different shape of the whole piece type.The diaphragm coupling relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. It is a high-performance flexible coupling with strong metal components. It does not require lubrication, and has a compact structure, high strength and long service life. , No rotation gap, not affected by temperature and oil pollution, with acid resistance, alkali resistance and corrosion resistance, suitable for high temperature, high speed, and corrosive medium operating conditions.

Details

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details

SWC type cross shaft universal coupling is a commonly used coupling.Utilizing the characteristics of its structure, it can make two shafts that are not on the same axis or that have a large angle of axis or that have a large axial movement continuously rotate at equal angular speed, and reliably transmit torque and motion.It can be widely used in metallurgy, lifting, engineering transportation, mining, petroleum, shipbuilding, coal, rubber, papermaking machinery and other heavy machinery industries to transmit torque in mechanical shafting.

Details