- Diaphragm coupling

- Gear coupling

- Snake spring coupling

- Pin coupling

- Cardan shaft

- Plum blossom/star coupling

- Roller chain coupling

- Tire coupling

- Elastic block coupling

- Flange coupling

- Safety coupling

- Expansion sleeve

- Power station oil station liquid couple accessories

|

|

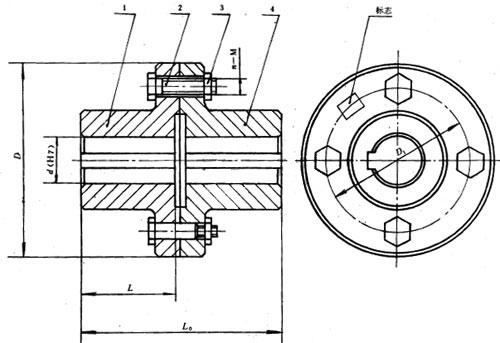

Flange coupling is a rigid coupling. It connects two flanged half couplings to the two shafts with ordinary flat keys, and then connects the two half couplings into one body with bolts to transmit motion And torque.There are two main structural forms of this coupling:

①Relying on reamed holes and bolts to realize the two-axis centering and relying on the bolt rod to bear extrusion and shear to transmit torque;

②It is centered by matching the convex shoulder on one half coupling with the groove on the other half coupling.The bolts connecting the two half-couplings can be ordinary bolts of grade A and B. The torque is transmitted by the frictional moment of the joint surface of the two half-couplings.

| model |

Nominal torque Tn(N·m) |

Allowable speed [n]r/min | Axle hole diameter d(H7) | Shaft hole length L | D | D1 | bolt | L0 |

Moment of inertia (kg.m2) |

weight (kg.m³) |

|||||

| Y type | J1 type |

Quantity n |

Diameter M | ||||||||||||

| iron | steel | iron | steel | Y type | J1 type | ||||||||||

| YL1 YLD1 | 10 | 8100 | 13000 |

10 11 |

10 11 |

25 | 22 | 71 | 53 | 3 (3) | M6 | 54 | 48 | 0.0018 | 0.94 |

|

12 14 |

12 14 |

32 | 27 | 68 | 58 | ||||||||||

|

16 18 19 |

16 18 19 |

42 | 30 | 88 | 64 | ||||||||||

|

20 - |

20 22 |

52 | 38 | 108 | 80 | ||||||||||

| YL2 YLD2 | 16 | 7200 | 12000 |

12 14 |

12 14 |

32 | 27 | 80 | 64 | 4 (4) | M6 | 68 | 58 | 0.0035 | 1.50 |

|

16 18 19 |

16 18 19 |

42 | 30 | 88 | 64 | ||||||||||

|

20 22 |

20 22 |

52 | 38 | 108 | 80 | ||||||||||

| YL3 YLD3 | 25 | 6400 | 10000 | 14 | 14 | 32 | 27 | 90 | 69 | 3 (3) | M8 | 68 | 58 | 0.0060 | 1.99 |

|

16 18 19 |

16 18 19 |

42 | 30 | ||||||||||||

| 88 | 64 | ||||||||||||||

|

20 22 |

20 22 24 |

52 | 38 | 108 | 80 | ||||||||||

| 128 | 92 | ||||||||||||||

| YL4 YLD4 | 40 | 5700 | 9500 |

18 19 |

18 19 |

42 | 30 | 100 | 80 | 3 (3) | M8 | 88 | 64 | 0.0093 | 2.47 |

|

20 22 24 |

20 22 24 |

52 | 38 | 108 | 80 | ||||||||||

|

25 - |

25 28 |

62 | 44 | 128 | 92 | ||||||||||

| YL5 YLD5 | 63 | 5500 | 9000 |

22 24 |

22 24 |

52 | 38 | 105 | 85 | 4 (4) | M8 | 108 | 80 | 0.013 | 3.19 |

|

25 28 |

25 28 |

62 | 44 | 128 | 92 | ||||||||||

|

30 - |

30 32 |

82 | 60 | 168 | 124 | ||||||||||

| YL6 YLD6 | 100 | 5200 | 8000 | 24 | 24 | 52 | 38 | 110 | 90 | 4 (4) | M8 | 108 | 80 | 0.017 | 3.99 |

|

25 28 |

25 28 |

62 | 44 | 128 | 92 | ||||||||||

|

30 32 - |

30 32 35 |

82 | 60 | 168 | 124 | ||||||||||

| YL7 YLD7 | 160 | 4800 | 7600 | 28 | 28 | 62 | 44 | 120 | 95 | 4 (3) | M10 | 128 | 92 | 0.029 | 5.66 |

|

30 32 35 38 |

30 32 35 38 |

82 | 60 | 168 | 124 | ||||||||||

| - | 40 | 112 | 84 | 228 | 172 | ||||||||||

| YL8 YLD8 | 250 | 4300 | 7000 | 32 35 38 |

32 35 38 |

82 | 60 | 130 | 105 | 4 (3) | M10 | 169 | 125 | 0.043 | 7.29 |

|

40 42 - |

40 |

112 | 84 | 229 | 173 | 6.53 | |||||||||

| YL9 YLD9 | 630 | 4100 | 6800 | 38 | 38 | 82 | 60 | 140 | 115 | 6 (3) | M10 | 169 | 125 | 0.064 | 9.53 |

| 112 | 84 | 229 | 173 | ||||||||||||

|

40 42 45 48 - |

40 42 45 48 50 |

||||||||||||||

| YL10 YLD10 | 630 | 3600 | 6000 |

45 48 50 55 - |

45 48 50 55 56 |

160 | 130 | 6 (4) | M12 | 0.112 | 12.46 | ||||

| - | 60 | 142 | 107 | 289 | 219 | ||||||||||

| YL11 YLD11 | 1000 | 3200 | 5300 | 50 55 56 |

50 55 56 |

112 | 84 | 180 | 150 | 8 (4) | M12 | 229 | 173 | 0.205 | 17.97 |

|

60 63 65 - |

60 63 65 70 |

142 | 107 | 289 | 219 | ||||||||||

| YL12 YLD12 | 1600 | 2900 | 4700 | 60 63 65 70 71 75 |

60 63 65 70 71 75 |

200 | 170 | 12 (6) | M12 | 0.443 | 30.62 | ||||

| - | 80 | 52 | 38 | 349 | 269 | 0.463 | 29.52 | ||||||||

| YL13 YLD13 | 2500 | 2600 | 4300 | 70 71 75 |

70 71 75 |

142 | 107 | 220 | 185 | 8 (6) | M16 | 289 | 219 | 0.646 | 35.58 |

|

80 85 - |

80 85 90 |

172 | 132 | 349 | 269 | ||||||||||

| YL14 YLD14 | 4000 | 2300 | 4800 | 80 85 90 95 |

80 85 90 95 |

172 | 132 | 250 | 215 | 12 (8) | M16 | 350 | 270 | 1.353 | 57.13 |

|

100 - |

100 110 | 212 | 167 | 430 | 340 | ||||||||||

| YL15 YLD15 | 6300 | 2000 | 3400 |

- - |

90 95 |

172 | 132 | 290 | 250 | 12 (6) | M20 | 350 | 270 | 2.854 | 89.59 |

|

100 110 120 - |

100 110 120 125 | 212 | 167 | 430 | 340 | ||||||||||

| YL16 YLD16 | 10000 | 1800 | 3000 |

- - 6 396 hab |

100 110 120 125 | 340 | 290 | 12 (6) | M24 | 5.271 | 119.57 | ||||

|

130 - |

130 140 | 252 | 202 | 510 | 410 | ||||||||||

| YL17 YLD17 | 14000 | 1600 | 2600 |

- - |

120 125 | 212 | 167 | 380 | 330 | 12 (6) | M24 | 430 | 340 | 9.139 | 171.71 |

| 130 140 150 | 130 140 150 | 252 | 202 | 510 | 410 | ||||||||||

| - | 160 | 302 | 242 | 610 | 490 | ||||||||||

| YL18 YLD18 | 20000 | 1400 | 2300 |

- - |

140 150 | 252 | 202 | 420 | 360 | 12 (6) | M30 | 510 | 410 | (17.883) | (263.5) |